Silicone / FKM / EPDM / Neoprene / Nitrile

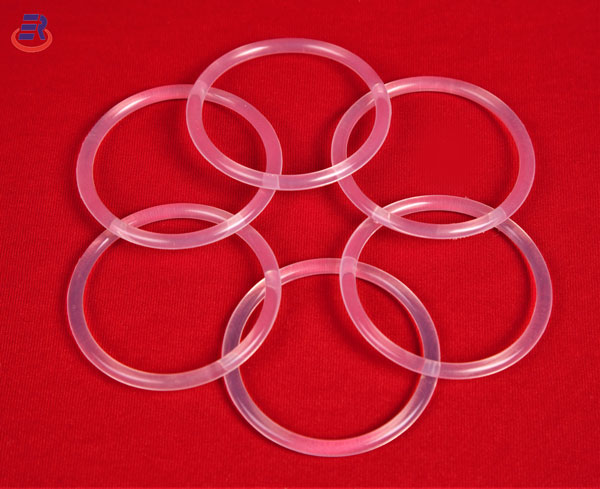

Eshita Rubber Pvt Ltd offers its wide range of O-Rings from 1.00 mm ID to 600 mm ID. Our O-Rings are manufactured on a hydraulic press with tightly controlled temperature, pressure and time which ensures accurate dimensions, glossy finish and invisible flash line, properly post cured and absolutely defect free articles. These O-Rings are aslo manufactured as per the dimensional tolerance specified by the customer or as per the International Standeard tolereance chart.

Application

Filter Housings

Membrance Filter Holder

Heat Exchangers

RMG Discharge Port

Pneumatic cylinders

Spray Guns

Other Sealing Applications

FEP Enacapsulated O-Rings

Eshita Rubber Pvt Ltd is FKM and EPMD Encapsulated O-Rings with FEP encapsulation are designed to address the growing problem of sealing in the most hostile chemical and temperature environments. It combines the best qualities of FEP material on the outside with its chemical interness and an elastomer on the inside for sesilience. This unique combination forms a highly effective, long lasting seal for the most demanding applications.

This O-Rings are comprised of FEP over Silicone, FKM or EPDM and can be used in temperatures from -75 F to +400F (-60 to +205C) depending upon the choice of elastomer core.

Why are Encapsulated O-Rings needed?

There are certain applications which prohibit the use of conventional rubber O-Ring seals. The use of hostile chemicals or extreme temperature (both high and low) during various processes can make effective sealing very difficult. The mail advantage encapsulated O-Ring have solid P.T.F.E. is that it has the chemical inertness whilst with its energising core, the O-Ring returns to its original form.

Application

Agitated Nastch Filter Dryer ( ANFD )

Reactors

Solvent Container Lid

Centrifuge Lid